How to Use a Star Plate to Make Pumped Stars

Star Plates -- Why use them to make

fireworks stars?

A star plate is a fast and easy way to make a lot of fireworks stars.This project builds on the skills and techniques which were introduced in Chapter 6 of the Turbo Pyro curriculum: How to Make Pumped Stars and Star Mines. If you have Turbo Pyro, you may want to review that chapter.

Fireworks stars can be made various ways: by cutting stars; or making box-stars and go-getters where the composition is packed into paper tubes; by rolling round stars in a star roller; or by pumping stars.

Pumping stars has some significant advantages. Very specific quantities of stars can be quickly produced for individual projects. These stars will all be of a consistent size and shape. The sharp edges on the top and bottom of the stars make the stars easier to light. And, since the stars are made with a minimal amount of water, they dry quickly.

This last quality of pumped stars can be especially useful. A batch of the stars can be pumped one day, primed if necessary immediately after pumping, dried overnight in a drying chamber, and used in devices the next day. This makes on-site device manufacturing possible at fireworks-club events, and really speeds up fireworks projects.

Pumped stars produce a single color or effect when they are used as they come out of the pump. But different color and effect stars can be sandwiched to produce a color-changing star, or a multiple effects such as a color-headed star, which leaves a charcoal or metal spark tail behind it.

There are basically two ways to pump stars: The stars in Turbo Pyro were pumped with a single piston and cylinder, which produces one star at a time.

1/2-Inch Star Pump

Now we'll step up our production rate by using a gang-pump called a star plate.

Skylighter TL3006 1/2-Inch Star Plate

Large All-Aluminum Star Plate

These stars are made by dampening a composition, compacting the composition with the star plate, and then pumping out the cylindrically shaped stars.

The large aluminum star plate shown above has the advantage that stars can be pumped in larger quantities, more quickly.

There are disadvantages of the large plate: more pressure must be applied to it to completely consolidate the stars, since there is more star surface area being compacted. So, it must often be used with a hydraulic press to ensure enough pressure is applied. Finally, the large plate costs hundreds of dollars more than the smaller one.

The TL3006 1/2-inch star plate can pump stars using only hand pressure combined with hand-mallet ramming. It is much less expensive than the large aluminum plate.

Since the pins in the pin-plate are brass inserted into a resin plate, they can sometimes come loose. This is remedied by applying a fillet of super-glue around the base of each pin where it meets the plate.

Apply the super-glue after ensuring that all the pins are completely seated into the plate. The tops of all the pins should align in one flat plane. After the glue has been applied, allow it to dry completely before using the plate to pump stars.

Applying Super-Glue to the Base of Each Star-Plate Pin

Chrysanthemum-6 Stars for This Project

Many different kinds of stars can be pumped with star plates: glitter stars, color stars, metal-spark-tailed stars, or charcoal-tailed stars.

Charcoal-tailed stars are the simplest and most foolproof type of star one can make. These stars can be made with a slow-burning composition, such as stars for long-hanging willow shells. Or fast-burning stars can be pumped to produce impressive spider web shells, with streaks of charcoal tails intertwining in the sky. Chrysanthemum-6 is used to produce those spider web stars.

Pumped stars made with Chrysanthemum-6 composition do not need to be primed. The star formula is so hot that the stars will catch fire and ignite about as readily as a black-powder prime would. But, if you really want to be particular, you're welcome to prime the stars anyway.

Chrysanthemum 6 Charcoal Stars

( about 228 1/2 x 1/2-inch starsor enough for three 4-inch star-shells or star-mines)

| Chemical | Factor | 16 Ounces | 450 Grams |

| Potassium nitrate | 0.55 | 8.8 ounces | 247.5 grams |

| Airfloat charcoal | 0.33 | 5.3 ounces | 148.5 grams |

| Sulfur | 0.07 | 1.1 ounces | 31.5 grams |

| Dextrin | 0.05 | 0.8 ounce | 22.5 grams |

(After the following steps the composition will be dampened with +10% (Factor of +0.1) distilled water. That will be 1.6 ounces (45 grams) of water, by weight.)

Often, particles of metals such as titanium, ferro-titanium, or aluminum are added to charcoal-streamer compositions to create "blonde," metal-spark tails when the stars burn.

But if metal particles are to be used in compositions that are to be pumped with star pumps or star plates, the size of the particles must be carefully chosen to avoid damaging the tooling, or binding the male and female parts of the tooling together, making them difficult to separate without damaging the tool.

Avoid using metal particles significantly smaller than the gap between the tooling pin and hole, or significantly larger than that gap.

Grinding Chemicals

First, before weighing any chemicals, verify the potassium nitrate and sulfur are fine enough to easily pass through a 40-mesh screen. If either of them won't, pulverize the individual chemical in a blade-type coffee mill or a ball-mill until it will easily go through the 40-mesh screen.Warning: If you need to grind chemicals in a blade-type coffee mill, only mill individual chemicals, one at a time--do not mill them after they have been mixed. Alternatively, the complete batch of star composition can be weighed out per the following instructions, and milled in a ball-mill. All ball milling safety precautions must be observed. Use only non-sparking lead or brass milling media.

Weighing and Mixing the Chemicals

Weigh each chemical individually into its own container. Tare the scale with the empty container on it. Then combine all chemicals into that container. The total weight of all the chemicals together should weigh what the total batch weight is in the formula. This double-check verifies no mistakes were made during the weighing.After confirming the weight, pour the chemical mixture into a mixing tub. Snap the lid tightly on the tub, and holding the lid on tight, shake the tub to mix the chemicals. The chemical mixture is now referred to as a chemical "composition" or "comp."

Screening the Mixed Composition

If you ball-milled the ingredients of your composition, you can omit this screening step.Now pour the composition out of the mixing tub onto a 20-mesh screen, and gently screen the mixture into another tub or onto a piece of kraft paper. Repeat this screening process twice to break up any clumps, and thoroughly mix all the ingredients.

Warning: This can be a messy and dusty process, which is best done outdoors on a still day and completely away from any sources of ignition.

Dampening the Composition -- Pay Close Attention

Weigh out the specified amount of distilled water. Double check its weight by pouring the water into another container sitting on the scale which has been tared.Be careful. The amount of water is critical. Too much water and your star-pumping will be messy, and your stars may never dry completely. Too little water and the stars will not hold together.

Getting the water just right cannot be overemphasized. Over-watering is the one problem you are most likely to have in making these stars.

With some experience, and depending on your particular chemicals, the amount of water can be adjusted slightly up or down from one batch of stars to the next. Keeping notes of exactly what you do in these batches is the best way to ensure manufacturing consistency.

Put the water into the tub of composition, close the tub, and holding the lid on, shake the tub vigorously.

Remove the tub's lid and, using gloved hands, work all the dampened composition into itself, rubbing any damp composition off the tub sides and lid.

Put the dampened composition onto the 20-mesh screen, and work it through the screen to completely disperse the water throughout the comp.

Put the composition back into the tub, close the tub, shake it again while holding the lid on tight, and then repeat the screening process one more time.

The star comp will now be an evenly and thoroughly dampened, fluffy composition, ready for pumping into stars.

Using the Star Plate to Pump 1/2-Inch Stars

Be sure you have everything in this list on hand before you begin using your star plate:- A mallet

- A ramming post to serve as a solid base on which to ram the stars

- The 1/2-inch star plate

- Rubber gloves

- A large flat-bottomed plastic tray or tub in which to fill the hole-plate

- A screen on which to dry the pumped stars

- Two blocks of 2x4 wood, slightly longer than the star plate

- A piece of waxed paper

- Tub of star comp

- Scoop for star comp

Materials and Tools Assembled and Ready for Star Pumping

Warning: Even though the star composition is damp, it is still flammable. As always, keep the tub of it closed unless some is being removed to work with. Remove any other flammables or fireworks devices from the work area to minimize exposure.

Note: Spraying the hole and pin plates with a dry, Teflon-type spray lubricant, such as Team McLube "Sailkote," and allowing the lubricant to dry, can prevent the star composition from sticking to them. This can make the star-pumping easier and less-messy.

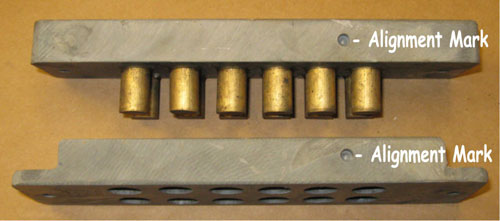

Before you start, find the alignment marks on the two parts of your star plate. These marks may be a cut or groove in the resin, or two holes as shown in the picture below, or some other mark. Test that the two halves of your plate actually fit together with the marks aligned.

Star Plate Alignment Marks

The first step to pumping the stars is to load the hole plate with star comp.

Put the hole plate into the bottom of the flat-bottomed tub. Then scoop a cup of star composition out of its tub and onto the hole plate. Close the tub of dry composition back up.

Using gloved hands, rub as much of the composition into the plate's holes as you can. Flip the plate over and repeat this process. The goal is to force as much of the composition into the plate as possible using hand pressure. Rub the excess composition off of the top of the hole plate.

Filling Hole Plate with Star Composition

Place the pin plate onto the hole plate, with the two plates' alignment marks lined up correctly. With the hole plate flat on the bottom of the filling tub, push down on the pin plate and compress the star comp as much as possible.

Mating Pin Plate with Comp-Filled Hole Plate

Removing the pin plate should reveal that the star composition in the holes has only been compressed enough to create depressions which are about 1/8-inch deep in each hole.

Mate the pin plate back up with the hole plate. Pick up the whole star-plate and rub off any excess star composition on the bottom of the hole plate.

Put a piece of waxed paper on one of the 2x4 blocks of wood. Place the bottom of the hole plate on the waxed paper. Now put the wood block onto the ramming post.

Placing Filled Star Plate on Waxed-Paper on Wood Block

Put the other 2x4 block on the top of the pin plate.

Now, starting gently and evenly, pound the whole block/plate assembly with the mallet to ram the stars as much as possible.

Ramming Star-Plate Assembly with the Mallet

About 8 solid whacks with the mallet will compress the stars nicely in the star plate.

Remove the star plate from between the wood blocks, and, using hand pressure, gently eject the stars from the hole plate onto the drying screen.

Using a star plate to make firework stars.

The pressed stars should be solid enough to withstand gentle compression between your fingers. Once they are dry they will be rock hard.

Repeat the filling, compressing, and ejecting steps until all the batches of stars have been pumped. This process resulted in 19 complete star plates full of stars from one batch of star composition.

The final batches are easier to fill and work with on an open, flat plastic tray as shown here.

Using a star plate to quickly make large batches of firework stars.

You can see below from the trial fit of the stars in a 4-inch paper shell hemisphere that about 35 stars fill the hemisphere. So, it will take about 70 stars to assemble a complete 4-inch aerial ball shell.

Finished Batch of 1/2-Inch Pumped Stars

These 228 stars will be enough to make three 4-inch aerial shells, or three 4-inch star mines, or a combination of them.

After the star composition was prepared, it took about 30-40 minutes to pump all 19 batches of the stars.

Drying the Stars

Warning: Always dry stars away from people and any property you care about. Drying stars have been known to spontaneously combust. If a stray spark were to ignite them, you could have a massive flash fire. To figure out the safest place to dry your stars, assume they will catch fire -- now where would you want that fire to happen?Pumped stars have a minimum of water in them, so they dry quickly. They will dry best in a warm, dry, shady location with moving air. Remember, moving air is more important than temperature. Exception: do not try to dry stars when it is freezing--unless you make Eskimo fireworks.

Long term, if you get serious about making fireworks stars, a drying chamber is best for drying stars. These stars will dry overnight in such a chamber. Here's an excellent project for making a fireworks drying chamber.

For best results, place the stars on a drying screen so that moving air can reach all sides of the stars including their bottoms. You can leave the stars on a paper plate in a safe, warm, breezy, and shady location. They will dry quickly there. Do not dry stars in the sun. Hot sunlight can cause the outside layer of the stars to bake into a hard shell. This can cause "driven-in" moisture that cannot evaporate from the stars.

Many folks use a food dehydrator to dry stars, as described in Turbo Pyro. That works well as long as all safety precautions are observed.

If you use a dehydrator, do it remotely using an extension cord, away from people and buildings. It is an electric device which can malfunction and cause a fire.

How do you know when the stars are completely dry?

One nifty way is to weigh them when they are fresh out of the star plate and still damp. Then re-weigh them after they have been drying for awhile.

This batch of stars ended up weighing 15.65 ounces when still damp, and after all the loose crumbly stuff was removed. (This is less than the initial 16 ounce weight of your dry mixed composition due to spillage, loose material that didn't actually end up in the stars, etc.)

That batch of stars was made with X amount of dry star composition, to which 0.1 x X (10%) water was added.

So, 1.1 x X = 15.65 ounces. X = 15.65/1.1 which equals about 14.25 ounces.

When the stars have lost all their water, and are completely dry, they will therefore weigh about 14.25 ounces.

To determine if the stars are good and dry then, I'll just weigh them to see how close to that 14.25 ounces they are. Reweighing them at time intervals will indicate how quickly they are drying, and when they stop losing weight they are dry.

Another good way to check for dryness is to put a few stars in a closed plastic baggie in the sun. If the stars are dry, almost no water will condense on the inside of the baggie.

These stars will dry very quickly in the optimal drying conditions described above.

As was mentioned, this Chrysanthemum 6 star formula is so easy to light that stars made with it will not require priming before they are used in fireworks devices.

Other star compositions may need priming, though.

Always store dry stars in a sealed plastic container in a safe storage area, preferably a magazine.

The best way to dispose of the waste star composition "crumblies" and the kraft-paper that covered the workbench is in a safe burn pile designated for "hot trash" (ed. note: not to be confused with "hot white trash.")

Tip: When you burn waste pyrotechnic material, the safest way is to make a line of the stuff vs. a pile. The first time you burn much waste comp, you may be very surprised at how fast it burns or flares up. More than one pyro has been seriously burned or killed this way. A line burns slower and smaller. Use a piece of fuse to light the material, if you have any doubts at all about this step.

Simple water-washing will completely clean all tooling and containers used in the star-making process.

Pump Out Hundreds of Stars Per Hour

1/2-Inch Star Plate Kit

Check Out the Kit & Order Here