How to Make Cut Fireworks Stars - Firefly Effect

Whether they are fired from a mine, an aerial shell, or a rocket heading, firefly stars produce a cloud of orange charcoal-sparks, with many silver flickering sparks flashing off and on, resembling fireflies on a hot summer night.

The effect is a beautiful but subtle one, so when a device containing firefly stars is fired, no other devices should be fired immediately afterward, until the many-seconds-long firefly display has had time to finish. Firefly-star shells are great when fired as volleys in a display, and then allowing the twinkling stars to fall gently, and to display completely before any other shells are fired.

Plastic-Can Rocket Headings Filled with Firefly Stars

The rocket headings were made with parts from Skylighter's 2-Inch Fireworks Shell Kit.

No time fuse was used. Fast-fuse (Skylighter #GN1205) was used instead. The rocket motors were made using the Speed Rockets project, and the rocket fuel was actually used to burst the rocket headings.

In the video of the rocket headings, the first and third headings were filled with firefly stars made with Skylighter #CH0155 "Mixed Firefly aluminum flake, +40-325 mesh." The stars in the second and fourth headings were made with Skylighter #CH0150 "Firefly aluminum flake, 10-12 mesh."

The two different aluminums both produce pleasing effects, although they are somewhat different from each other. Because it contains smaller particles, the CH0155 aluminum produces a dense cloud of more fine, white sparks of various sizes. The CH0150 aluminum, with larger particles, produces a slightly more sparse cloud of larger, evenly sized, white sparks, which hang for a longer time, blinking on and off.

Like many high-charcoal-content stars, firefly stars tend to be more fragile, so they should be projected from devices with softer, more gentle bursts. Stick to plain, black powder burst without any augmentation (such as harder flash or whistle breaks).

This quote from Robert Cardwell, in Pyrotechnica XII, sums up the firefly effect wonderfully:

"When the stars are made successfully, each star forms many glowing flakes of a charcoal-type effect, slowly floating down, which periodically and suddenly burn brightly silver, but in a different, more subtle fashion than with a strobe effect. It is more subdued, mysterious and majestic than strobe-type flashes. This effect hangs in the air, slowly descending for up to 60 seconds if a wind isn't blowing..."

Besides the cut star method which will be shown in this project, firefly stars can also be made by pumping them with comet pumps or star plates, using less water than when they are cut.

Star-cutting, as will be shown, is nicely applicable to many types of stars: firefly stars, charcoal stars, zinc stars, glitter stars, and many color-star compositions.

Common Star Sizes for Various Size Aerial Shells

These dimensions work whether the stars are round or square/cut.

For 4-inch mines or shells, 1/2-inch finished-primed stars would be ideal. For 3-inch devices, the 3/8-inch finished star size should work fine.

So, a one-pound batch of stars shown below, which will weigh about 20 ounces when primed and dried, will make approximately four to six 3-inch shells, or two to four 4-inch shells.

(This amount of water is approximate, and should be added slowly and carefully, with the end result being a workable composition putty.)

Several years ago, John Glasswick, a well-known fireworker, shared the following slightly modified formula, which he stated he'd arrived at after trying lots of experiments designed to improve the number of fireflies in his starburst cloud. His results were verified as being valuable by several other master-fireworkers. This improved formula simply adds 6 more parts of potassium nitrate to the original formula above.

(This amount of water is approximate, and should be added slowly and carefully, with the end result being a workable composition putty.)

I personally found both formulas to produce very comparable results, but if you try the first formula, and have trouble with it producing enough firefly sparks, you might want to try the second one.

Additionally, the original firefly formula, developed by Jerry Taylor and provided to Skylighter by Steve Majdali, specified that it be bound with wheat paste. This is simply old-fashioned wallpaper paste, employed by many folks to paste paper on cylinder shells.

I tried firefly stars bound with thin wheat paste instead of dextrin. It produced almost identical effects as stars bound with dextrin. But the composition dampened with the wheat paste was much less sticky and easier to work with.

So, if you find your dextrin-bound composition to be sticky and challenging to work with, you might find some old-fashioned wheat paste. It comes as a dry powder. If you use wheat paste/powder, you change the way you dampen your star mix: First mix some up into a thin paste in a blender. Then add enough to the dry composition to produce a damp putty which can then be cut as described below. Remember to eliminate the dextrin from the formula.

If one or more of the individual chemicals is lumpy or too coarse to pass through a 40-mesh screen, it will need to be milled into a finer powder. You can use a ball mill, as shown in this project:

Quick & Easy Black Powder Ball Mill

If you use a ball mill, mill each individual chemical dry in the mill jar for 30 minutes. But DO NOT mill the 80-mesh charcoal or the aluminum.

If you don't have a ball mill, blade mills are an easy, safe way to finely granulate any chemical. You can use a blade-type coffee-mill, or a single serving blender, shown in the photos and video below, currently available at Walmart for less than $20. This is what we'll be using in this project:

Walmart Model #898679

If you're using a blade-type mill, perform the following steps:

Verify the chemicals (other than the aluminum) are granulated fine enough that individual chemicals will each easily pass through a 40-mesh screen.

Warning: Only grind individual chemicals, one at a time--never combinations--and clean the mill out between chemicals. Never mill metal particles.

Grinding One Chemical in a Blade-Type Coffee Mill

Close the mixing tub tightly, and shake it while holding the lid on securely.

Place the 40-mesh screen on a sheet of paper, and pour the composition onto the screen. With gloved hands, gently rub the chemical mixture through the screen and onto the paper. Pick the paper up, pour the screened comp back into the tub, close it, and shake again.

Repeat this screening and shaking two more times, so that the composition has been shaken 4 times, and screened 3 times, for complete mixing.

Repeat this process for the firefly star composition, except do not weigh or add the firefly aluminum yet.

Once the composition has been shaken 4 times, and screened 3 times, add the pre-weighed firefly aluminum to the mixing tub, and shake the composition thoroughly.

Tare the scale to 0.00 with a spray bottle of water sitting on it. Pour the mixed star composition into a stainless-steel mixing pot.

Start spraying water into the composition, occasionally working the moisture into the powder, and wiping the pot's sides clean with your hand.

Weigh the water spray bottle occasionally and pay attention to when the recommended amount of water is getting close to being used up. At that point, the scale will show a negative weight. The composition should turn into a workable putty which isn't too wet, but which does not crumble when cut with a knife. Dump the comp into a plastic tub.

A word about too much water: the tendency of most people is to add too much water. So, when you are first learning this process, be stingy with your water. Too much water, and your stars will "wilt" or be sticky when you try to cut and separate them. Too little and they will crumble.

Try this: If it sticks together, holds its shape, is only slightly glossy on its surface, and can be sliced cleanly in two with your cutting knife without crumbling, it's about right.

Pack the putty down into an even layer inside the plastic tub.

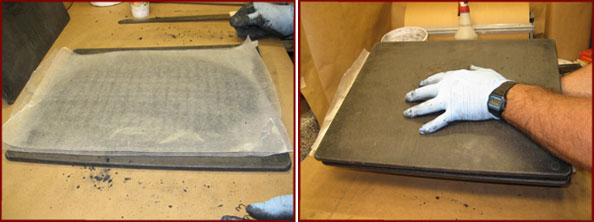

Two plastic cutting boards, about 14 x 17 inches, are ideal for cutting stars. Tear off 4 sheets of waxed paper slightly longer than the cutting boards. Dump the composition out of the plastic tub onto your gloved hands.

Work the putty in your hands to smooth and round it out. Put it onto one of the waxed paper sheets on a cutting board. Gently pat the composition out into a smooth "round."

Surround the patty with four wood dowels the same thickness you want your stars to be. I'm using 7/16-inch dowels here, which end up making for 1/2-inch stars once they get a little thicker after priming. Cover the patty with a second sheet of waxed paper. Use a rolling pin as shown to start rolling the composition out the same thickness as the dowels.

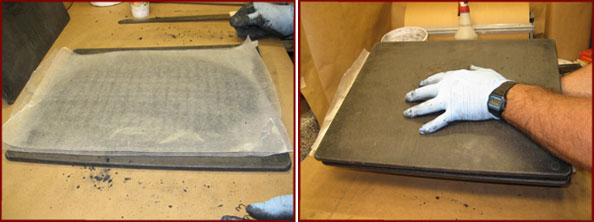

Roll the patty out in all directions until it is the same thickness as the wood dowels. Remove the top sheet of waxed paper and dispose of it. Remove the dowel spacers.

Sprinkle about 1/4 of the prime composition evenly onto the patty.

Cover the primed patty with a piece of waxed paper, and fold the top and bottom sheets of paper over at one end of the cutting board.

Place the second cutting board on top of the patty, and holding the folded-paper end downward to catch any spilling prime, flip the cutting boards over. Now remove the first piece of waxed paper and dispose of it.

Prime the second side of the star patty with the second 1/4 of the prime composition.

Using a sharp, thin, straight-edged cutting knife, begin cutting strips off the patty the same width/thickness as the wood dowels. Roll each strip over--90 degrees--as it is cut, so that the cut strips have primed edges against each other. This will leave all the strips with an unprimed edge up. (The knife shown here was purchased at McMaster Carr, item # 3851A11.)

Continue cutting strips off the patty, flipping them over, and sliding them against the strips which were previously cut.

When the whole patty has been cut into strips, which have primed edges against each other, sprinkle the third 1/4 of the prime onto the unprimed top of the strips.

Place the fourth sheet of waxed paper on top of the primed strips, and put the cutting board on top of that. Push down lightly on the top cutting board to secure the cut strips, and then flip the whole shebang over.

Remove the top cutting board and the top sheet of waxed paper, and dispose of the paper. Apply the last 1/4 of the prime to the top of the star strips.

Using the knife as a straight-edge, push the strips to one side of the cutting board, aligning the ends of all the strips. Begin cutting the final stars off the strips, the same width as the original dowel spacers, and flipping the stars over as before as they are cut.

When all the strips have been cut into individual stars, gently roll the stars over onto themselves, to evenly distribute all the loose prime onto all the stars' sides.

Gently pour the stars into a flat-bottomed plastic tub. Separate any stars which are stuck to each other. Gently tumble the stars in the tub, to more completely apply all the loose prime to them.

Pour all the stars from the tub onto a drying screen.

Gently separate the stars so there is air space between all of them.

Smile and admire your handiwork: evenly cut, sized, and primed stars on drying screens. Place the screens in a warm, dry, safe location, with gently moving air able to completely circulate around them. After the stars have air-dried for a day or two, you can speed up the final drying by putting them in a drying chamber.

When the stars are completely dry, you should be able to split one with a sharp knife, and the insides of the star should be dry and "crispy."

The stars are now ready to be used in a wide variety of fireworks devices.

All the chemicals you'll need to make 5 pounds of primed, beautiful firefly stars

The effect is a beautiful but subtle one, so when a device containing firefly stars is fired, no other devices should be fired immediately afterward, until the many-seconds-long firefly display has had time to finish. Firefly-star shells are great when fired as volleys in a display, and then allowing the twinkling stars to fall gently, and to display completely before any other shells are fired.

Plastic-Can Rocket Headings Filled with Firefly Stars

The rocket headings were made with parts from Skylighter's 2-Inch Fireworks Shell Kit.

No time fuse was used. Fast-fuse (Skylighter #GN1205) was used instead. The rocket motors were made using the Speed Rockets project, and the rocket fuel was actually used to burst the rocket headings.

In the video of the rocket headings, the first and third headings were filled with firefly stars made with Skylighter #CH0155 "Mixed Firefly aluminum flake, +40-325 mesh." The stars in the second and fourth headings were made with Skylighter #CH0150 "Firefly aluminum flake, 10-12 mesh."

The two different aluminums both produce pleasing effects, although they are somewhat different from each other. Because it contains smaller particles, the CH0155 aluminum produces a dense cloud of more fine, white sparks of various sizes. The CH0150 aluminum, with larger particles, produces a slightly more sparse cloud of larger, evenly sized, white sparks, which hang for a longer time, blinking on and off.

Like many high-charcoal-content stars, firefly stars tend to be more fragile, so they should be projected from devices with softer, more gentle bursts. Stick to plain, black powder burst without any augmentation (such as harder flash or whistle breaks).

This quote from Robert Cardwell, in Pyrotechnica XII, sums up the firefly effect wonderfully:

"When the stars are made successfully, each star forms many glowing flakes of a charcoal-type effect, slowly floating down, which periodically and suddenly burn brightly silver, but in a different, more subtle fashion than with a strobe effect. It is more subdued, mysterious and majestic than strobe-type flashes. This effect hangs in the air, slowly descending for up to 60 seconds if a wind isn't blowing..."

Besides the cut star method which will be shown in this project, firefly stars can also be made by pumping them with comet pumps or star plates, using less water than when they are cut.

Star-cutting, as will be shown, is nicely applicable to many types of stars: firefly stars, charcoal stars, zinc stars, glitter stars, and many color-star compositions.

How large should firefly stars be?

This chart provides a common starting point when making stars for different size aerial shells:

Common Star Sizes for Various Size Aerial Shells

These dimensions work whether the stars are round or square/cut.

For 4-inch mines or shells, 1/2-inch finished-primed stars would be ideal. For 3-inch devices, the 3/8-inch finished star size should work fine.

How many firefly stars should be made?

This will depend a bit on whether cylindrical shells or ball shells will be used--cylindrical shapes hold more stars than spheres. But, as a starting point, 3-inch devices will use about 3-5 ounces of stars, and 4-inch devices will use about 5-10 ounces of the stars.So, a one-pound batch of stars shown below, which will weigh about 20 ounces when primed and dried, will make approximately four to six 3-inch shells, or two to four 4-inch shells.

Firefly star formula

This formula for firefly stars is provided by Skylighter along with the firefly aluminum that it sells:| Chemical | Parts | % | Factor | 16 Oz | 450 Grams |

| Potassium nitrate | 49 | 45% | 0.45 | 7.2 oz | 202.5 g |

| Charcoal, airfloat | 29 | 27% | 0.27 | 4.3 oz | 121.5 g |

| Charcoal, 80-mesh | 11 | 10% | 0.10 | 1.6 oz | 45 g |

| Sulfur | 9 | 8% | 0.08 | 1.3 oz | 36 g |

| Firefly aluminum | 5 | 5% | 0.05 | 0.8 oz | 22.5 g |

| Dextrin | 5 | 5% | 0.05 | 0.8 oz | 22.5 g |

| Water | +39 | +36% | +0.36 | +5.75 oz | +162 g |

(This amount of water is approximate, and should be added slowly and carefully, with the end result being a workable composition putty.)

Several years ago, John Glasswick, a well-known fireworker, shared the following slightly modified formula, which he stated he'd arrived at after trying lots of experiments designed to improve the number of fireflies in his starburst cloud. His results were verified as being valuable by several other master-fireworkers. This improved formula simply adds 6 more parts of potassium nitrate to the original formula above.

| Chemical | Parts | % | Factor | 16 Oz | 450 Grams |

| Potassium nitrate | 55 | 48% | 0.48 | 7.7 oz | 216 g |

| Charcoal, airfloat | 29 | 25% | 0.25 | 4 oz | 112.5 g |

| Charcoal, 80-mesh | 11 | 10% | 0.10 | 1.6 oz | 45 g |

| Sulfur | 9 | 8% | 0.08 | 1.3 oz | 36 g |

| Firefly aluminum | 5 | 4% | 0.04 | 0.6 oz | 18 g |

| Dextrin | 5 | 5% | 0.05 | 0.8 oz | 22.5 g |

| Water | +41 | +36% | +0.36 | +5.75 oz | +162 g |

(This amount of water is approximate, and should be added slowly and carefully, with the end result being a workable composition putty.)

I personally found both formulas to produce very comparable results, but if you try the first formula, and have trouble with it producing enough firefly sparks, you might want to try the second one.

Additionally, the original firefly formula, developed by Jerry Taylor and provided to Skylighter by Steve Majdali, specified that it be bound with wheat paste. This is simply old-fashioned wallpaper paste, employed by many folks to paste paper on cylinder shells.

I tried firefly stars bound with thin wheat paste instead of dextrin. It produced almost identical effects as stars bound with dextrin. But the composition dampened with the wheat paste was much less sticky and easier to work with.

So, if you find your dextrin-bound composition to be sticky and challenging to work with, you might find some old-fashioned wheat paste. It comes as a dry powder. If you use wheat paste/powder, you change the way you dampen your star mix: First mix some up into a thin paste in a blender. Then add enough to the dry composition to produce a damp putty which can then be cut as described below. Remember to eliminate the dextrin from the formula.

Black powder prime formula

This simple black powder prime will be used during the star-cutting process to prevent the stars from sticking together, and to ensure good ignition when the stars are used in fireworks devices. About four ounces of prime is used per pound of stars.| Chemical | % | Factor | 4.2 Oz | 120.5 G |

| Potassium nitrate | 75% | 0.75 | 3 oz | 86 g |

| Charcoal, airfloat | 15% | 0.15 | 0.6 oz | 17 g |

| Sulfur | 10% | 0.10 | 0.4 oz | 11.5 g |

| Dextrin | +5% | +0.05 | 0.2 oz | 6 g |

Preparing the chemicals

The potassium nitrate, airfloat charcoal, sulfur, and dextrin should all be free-flowing, and fine enough to pass easily through a 40-mesh screen.If one or more of the individual chemicals is lumpy or too coarse to pass through a 40-mesh screen, it will need to be milled into a finer powder. You can use a ball mill, as shown in this project:

Quick & Easy Black Powder Ball Mill

If you use a ball mill, mill each individual chemical dry in the mill jar for 30 minutes. But DO NOT mill the 80-mesh charcoal or the aluminum.

If you don't have a ball mill, blade mills are an easy, safe way to finely granulate any chemical. You can use a blade-type coffee-mill, or a single serving blender, shown in the photos and video below, currently available at Walmart for less than $20. This is what we'll be using in this project:

Walmart Model #898679

If you're using a blade-type mill, perform the following steps:

Verify the chemicals (other than the aluminum) are granulated fine enough that individual chemicals will each easily pass through a 40-mesh screen.

Warning: Only grind individual chemicals, one at a time--never combinations--and clean the mill out between chemicals. Never mill metal particles.

Grinding One Chemical in a Blade-Type Coffee Mill

Mixing the compositions

Weigh each chemical for the black powder prime composition in a weighing cup, and dump those individual chemicals into a mixing tub. Reweigh the total composition to ensure that it totals the weight that the formula calls for. This ensures that each individual chemical was weighed correctly.Close the mixing tub tightly, and shake it while holding the lid on securely.

Place the 40-mesh screen on a sheet of paper, and pour the composition onto the screen. With gloved hands, gently rub the chemical mixture through the screen and onto the paper. Pick the paper up, pour the screened comp back into the tub, close it, and shake again.

Repeat this screening and shaking two more times, so that the composition has been shaken 4 times, and screened 3 times, for complete mixing.

Repeat this process for the firefly star composition, except do not weigh or add the firefly aluminum yet.

Once the composition has been shaken 4 times, and screened 3 times, add the pre-weighed firefly aluminum to the mixing tub, and shake the composition thoroughly.

Dampening the firefly star composition

Tare the scale to 0.00 with a spray bottle of water sitting on it. Pour the mixed star composition into a stainless-steel mixing pot.

Start spraying water into the composition, occasionally working the moisture into the powder, and wiping the pot's sides clean with your hand.

Weigh the water spray bottle occasionally and pay attention to when the recommended amount of water is getting close to being used up. At that point, the scale will show a negative weight. The composition should turn into a workable putty which isn't too wet, but which does not crumble when cut with a knife. Dump the comp into a plastic tub.

A word about too much water: the tendency of most people is to add too much water. So, when you are first learning this process, be stingy with your water. Too much water, and your stars will "wilt" or be sticky when you try to cut and separate them. Too little and they will crumble.

Try this: If it sticks together, holds its shape, is only slightly glossy on its surface, and can be sliced cleanly in two with your cutting knife without crumbling, it's about right.

Pack the putty down into an even layer inside the plastic tub.

Cutting firefly stars

Two plastic cutting boards, about 14 x 17 inches, are ideal for cutting stars. Tear off 4 sheets of waxed paper slightly longer than the cutting boards. Dump the composition out of the plastic tub onto your gloved hands.

Work the putty in your hands to smooth and round it out. Put it onto one of the waxed paper sheets on a cutting board. Gently pat the composition out into a smooth "round."

Surround the patty with four wood dowels the same thickness you want your stars to be. I'm using 7/16-inch dowels here, which end up making for 1/2-inch stars once they get a little thicker after priming. Cover the patty with a second sheet of waxed paper. Use a rolling pin as shown to start rolling the composition out the same thickness as the dowels.

Roll the patty out in all directions until it is the same thickness as the wood dowels. Remove the top sheet of waxed paper and dispose of it. Remove the dowel spacers.

Sprinkle about 1/4 of the prime composition evenly onto the patty.

Cover the primed patty with a piece of waxed paper, and fold the top and bottom sheets of paper over at one end of the cutting board.

Place the second cutting board on top of the patty, and holding the folded-paper end downward to catch any spilling prime, flip the cutting boards over. Now remove the first piece of waxed paper and dispose of it.

Prime the second side of the star patty with the second 1/4 of the prime composition.

Using a sharp, thin, straight-edged cutting knife, begin cutting strips off the patty the same width/thickness as the wood dowels. Roll each strip over--90 degrees--as it is cut, so that the cut strips have primed edges against each other. This will leave all the strips with an unprimed edge up. (The knife shown here was purchased at McMaster Carr, item # 3851A11.)

Continue cutting strips off the patty, flipping them over, and sliding them against the strips which were previously cut.

When the whole patty has been cut into strips, which have primed edges against each other, sprinkle the third 1/4 of the prime onto the unprimed top of the strips.

Place the fourth sheet of waxed paper on top of the primed strips, and put the cutting board on top of that. Push down lightly on the top cutting board to secure the cut strips, and then flip the whole shebang over.

Remove the top cutting board and the top sheet of waxed paper, and dispose of the paper. Apply the last 1/4 of the prime to the top of the star strips.

Using the knife as a straight-edge, push the strips to one side of the cutting board, aligning the ends of all the strips. Begin cutting the final stars off the strips, the same width as the original dowel spacers, and flipping the stars over as before as they are cut.

When all the strips have been cut into individual stars, gently roll the stars over onto themselves, to evenly distribute all the loose prime onto all the stars' sides.

Gently pour the stars into a flat-bottomed plastic tub. Separate any stars which are stuck to each other. Gently tumble the stars in the tub, to more completely apply all the loose prime to them.

Pour all the stars from the tub onto a drying screen.

Gently separate the stars so there is air space between all of them.

Smile and admire your handiwork: evenly cut, sized, and primed stars on drying screens. Place the screens in a warm, dry, safe location, with gently moving air able to completely circulate around them. After the stars have air-dried for a day or two, you can speed up the final drying by putting them in a drying chamber.

When the stars are completely dry, you should be able to split one with a sharp knife, and the insides of the star should be dry and "crispy."

The stars are now ready to be used in a wide variety of fireworks devices.

Make Your Own Beautiful Firefly Stars

Firefly Star Kit

Check Out the Kit & Order Here