How to Make Firework Mines

Introduction

There is a beautiful photo on the cover of Dr. Takeo Shimizu's Fireworks, The Art, Science and Technique (FAST). At the top of the picture is a huge, double-petaled, fireworks-shell starburst, with several smaller star-flowers between it and the ground. And, at the very bottom of the shot is a spray of stars shooting upward from the ground where the shells were fired: a mine.

Fireworks Mine at Bottom of Photo on Cover of "FAST"

Similarly, the back cover of Hardt's Pyrotechnics shows a rainbow of 5 colored mine-shots, with corresponding colors of small and large starbursts over each one.

Rainbow of Mines and Aerial Shells on Back Cover of Hardt's "Pyrotechnics"

Fireworks mines, or star-mines, can be used in conjunction with aerial shells to create such an effect, filling in the low sky as the starbursts fill the middle and high sky.

These devices are also very effective during a display when they are fired as a mine-run: a series of mines fired in sequence from various spots on the field in harmony with beats of music in the soundtrack.

A single mine, a mine-run, or a wall of simultaneously fired mines all serve to bring the audience's attention back down to the ground, providing contrast and variety during a fireworks display.

For precise timing of electrically fired mines, putting the electric match right down in the lift powder eliminates the objectionably noticeable, split-second delay, which occurs when a length of quickmatch leader is ignited by the electric match.

If I am going to put the e-match into the lift powder, I still attach a couple of inches of quickmatch to the electric match, with the e-match's protective shroud in place. This ensures that quite a bit of flame will be introduced into the lift powder, and it further protects the e-match from premature ignition due to shock or friction.

One of the clubs I belong to, The Bluegrass Pyrotechnics Guild, has assembled and fired literally thousands of 4-inch mines over the years for our displays at the PGI annual conventions. These devices can be very easily constructed, and they provide a nice hand-made touch to a fireworks show.

In this article I'll detail two methods of constructing 4-inch mines. But, these methods can be applied to any size mine, from 1-3/4-inch through 6-inch models. Simply by varying the size of the stars, the materials used in the assembly, the amount of lift powder, and the size of the mortar from which they are fired, mines can be tailored in size to any effect and any venue.

Making the Stars

Each 4-inch mine will use about one pound of stars. I like to use 1/2-inch stars in 4-inch shells and mines, and in mines, I prefer a fast-burning star, which burns out before it reaches apogee and begins to fall back to the ground.For this project I'll use two variations of one type of star, commonly known as Gold Spider Web (Ofca's Volume 5, Mastering Cut Stars the Easy Way) or Chrysanthemum 6 (Shimizu's FAST). This is a very fast-burning charcoal streamer star which is easy to make, and which produces bright streaks of sparks in the sky.

So the final working formula was:

| Chrysanthemum 6 | Ratio | 16-ounce batch |

| Potassium nitrate | 0.55 | 8.8 ounces |

| Charcoal, airfloat | 0.33 | 5.3 ounces |

| Sulfur | 0.07 | 1.1 ounces |

| Dextrin | 0.05 | 0.8 ounces |

The individual chemicals are screened through a 100-mesh screen, and any that will not pass the screen are milled in a coffee grinder until they will pass. (I have a grinder that I only use on oxidizers like the potassium nitrate, and one for fuels such as charcoal. Except for when I am ball-milling black powder, I never mill complete compositions, only individual chemicals.)

After I screen them individually, I mix them through the 100-mesh screen, and then shake them in a closed plastic tub. 1.3 ounces of water is added (+8%) to the composition, and it is thoroughly shaken in the closed tub once again. The dampened composition is then pushed through a 20-mesh kitchen colander to completely incorporate the moisture into the composition.

I use my 1/2-inch star plate to press 1/2-inch diameter by 1/2-inch long stars, which I dry overnight in the drying chamber.

The stars are then primed, and dried overnight again.

I make two, 16-ounce batches like this, and one 16-ounce batch of the same composition with 3.2 ounces (+20%) of 10-185 mesh spherical titanium (CH3001) added to the composition after all the 100-mesh screening is done. I never put any metals through my fine screens. The addition of this titanium will produce bright silver-white sparks as the stars burn, creating a silver-streamer star.

So, with these three, one-pound batches of stars, I can now proceed to make three, 4-inch mines.

Mine Assembly

There are some extremely simple ways to assemble mines. "Bag Mines" can be as simple as a paper bag with some lift powder in a baggie on the end of a fuse-leader inserted into the bottom of it. Then some stars are poured in, the neck of the bag is tied closed and she's ready to fire.In Introductory Practical Pyrotechnics, Tom Perigrin shows how to make a simple mine by installing a baggie of lift on a quickmatch leader, sliging that into a cardboard-tube mortar. Then dropping in some stars, bundled in some tissue paper, into the tube.

These simple mines are functional, but they'll typically not fire all the stars out the top of the mortar together and in a straight column of fire. Because there are some stars to the sides of the lift powder, they get fired a bit sideways and bounce around a bit in the mortar before they exit. Some of these stars can "ploof" out of the gun and drop onto the ground.

So, I like the following slight variations on the simple-mine theme. They are more effective at getting all the stars lit and out of the gun in a straight-up spray of stars.

Typically, mines use the same amount of lift black powder, and the same amount of stars, as a cylindrical star shell of the same diameter. I like to refer to the charts on Pages 138-140 of The Best of AFN II to determine these amounts.

For a single-break, 4-inch cylindrical shell, 1.5 - 2 ounces of commercial 2FA black powder is recommended for the lift powder. I'll use 1.75 ounces in these mines.

I have made three 24-inch lengths of homemade quickmatch for the mine leaders. Similar lengths of commercial quickmatch, or super-fast paper fuse (GN1205) (wrapped in aluminum foil duct tape), can also be used as mine leaders.

Quickmatch Fuse-Leaders for Fireworks Mines

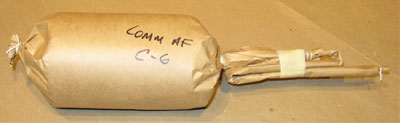

I then weigh out the three 1.75-ounce loads of 2FA lift powder, and put them in individual plastic baggies. The one-inch of black match protruding from the quickmatch leaders is folded back on itself, and then inserted into a baggie of lift. Masking tape is used to seal the baggie around the leader, and the extra plastic trimmed off with scissors. Then a final wrap of masking tape seals the baggie/tape to the quickmatch.

Installing Quickmatch Leaders into Baggies of 2FA Black Powder Lift

Method #1 - The High Quality Method

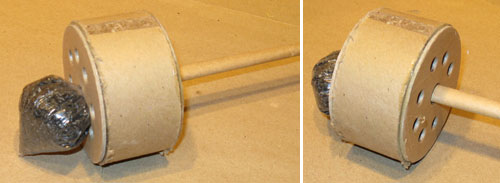

If I'm only going to make a few mines, and I want them to be top-quality, I build them this way.First I make a "piston" to go between the stars and the black powder lift charge. Here's a photo-essay of that process. It uses two 4-inch kraft discs, a 2-inch length of 3/4-inch ID tube (TU2053 or TU1065 or TU1068), and a 2-inch length of 3-3/8-inch or 3-1/2-inch OD tube.

Places like HarborFreight.com sell the sets of hollow gasket punches for ridiculously low prices. I much prefer to make the holes in discs with the punches instead of with a drill.

This piston will allow the lift-gasses to pass through it, igniting the stars, and will evenly push the stars out of the mortar and into the air in a tight column.

Assembling a Piston to Go Between Stars and Lift Powder in a Fireworks Mine

The center holes in the discs are 1/2-inch diameter and are large enough to allow the quickmatch leader to be threaded through them. The other holes are 3/8-inch diameter, keeping these holes smaller than the size of the stars that I am using.

Quickmatch Leader Threaded Through Mine Piston

Now, I position the piston on an 18x24-inch piece of kraft paper as shown. The paper is rolled up around the piston and glued to itself with hot-glue. Then the end with the baggie of lift powder is gathered together, tied with string in a clove-hitch knot, and trimmed with scissors. This is my mine casing.

Kraft paper is available from stores like Staples or Costco (white butcher paper), on-line from places like ULine.com, or paper grocery bags can be used.

Rolling Mine Piston and Lift/Leader Up in Kraft Paper, Tying Lift End Closed and Trimming with Scissors

Now, it's a simple matter of dumping the pound of stars into the open end of the mine casing, gathering the kraft paper around the leader, and tying it securely in place.

When filling a mine like this, I like to keep the depth of the stars equal to the diameter of the mine. So 3-4 inches of stars in this mine is my goal.

Filling the Mine Casing with Stars, and Tying the Paper Closed Around Mine Leader

A piece of Visco fuse is inserted and secured into the end of the leader, which is then S-folded. A safety cap can be installed over the fuse, and a band of masking tape sticky-side-out, followed by a band of tape sticky-side-in, secures the bundle until the mine is to be loaded into a mortar.

Completed Fireworks Mine

Here are shots of the two mines made this way. They had different types of charcoal in the stars, commercial airfloat and homemade poplar airfloat, but I didn't see any significant difference between the two.

4-Inch Chrysanthemum 6 Star-Mines

As you can see, the piston pushed all the stars out evenly, and very high. Nice, bright, fast and dramatic mines.

Method #2 - The Quick Method

The above "high-quality" method produces very nice, traditional mines, but it is a bit time-consuming. When the Bluegrass guild wants to construct several hundred mines in an afternoon, we've developed the following system. It is quick and easy, and while it does not allow the use of quite as many stars, and the quality of the mine-display is not quite as nice, it is a very effective method for producing large quantities of mines quickly.We start with the same lift-bag/leader configuration as shown above.

Two disposable plastic drinking cups are used for each mine. For these 4-inch mines, cups that are 3-5/8-inches in diameter at the top are ideal.

One of the cups has its bottom perforated with a hot, pencil-tip soldering iron. I've tried using a drill for this operation, but often the cup-bottom will crack when doing so.

Holes Melted in Bottom of Mine Cup With Hot Soldering Iron

The mine leader is inserted through the center hole in the cup. That whole assembly is placed into the second, intact cup, and the perforated cup is filled with stars. In this case, it held 12 ounces of the stars.

Lift and Leader Installed into Perforated Cup, Placed Into Solid Cup, and Filled With Stars

Then the assembled mine is sealed with four, 9-inch strips of aluminum-foil duct-tape. The leader is completed with Visco fuse and S-folding as shown with the paper-cased mine in the Method #1 above.

4-Inch Plastic-Cup Mine Sealed With Aluminum-Foil Duct-Tape, and Ready to Be Fired

This mine was made with the silver-streamer stars, which contained spherical titanium. While it did not contain the same quantity of stars as the previous two mines, and it did not fire quite as high as they did, it was still a very nice, bright mine.